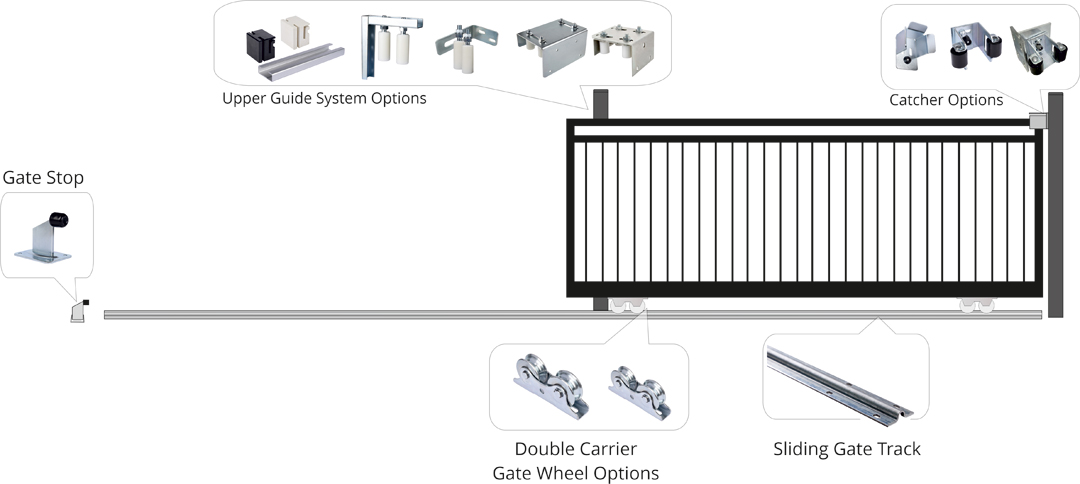

Top Guide System Options

Multiple options available to choose from based on two factors:

1. Protrusions above the gate such as spears.

2. Gates total thickness including and cladding material if applicable.

210mm Bracket with 100mm Nylon Rollers

The 210mm Longer overhead bracket allows for a full adjustment up to maximum total gate thickness of 115mm. This is typically the go to in most cases when using an overhead bracket and roller arrangement as it allows for all standard gate thickness and also surface mounted horizontally clad gates or gates that need a larger set back away from the post. It is constructed of DUAL C channels providing the best rigidity and with no flex under load.

Four Point Roller System A (60-105mm)

Best suited for heavier gates the for point roller system shares the load across the four rollers (as opposed to two) It can support an effective gate thickness from 60-105mm with adjustment in the slotted channels. The secondary plate optionally can be used to additionally support bracket by welding or screwing to a secondary support post creating a tunnel style installation.

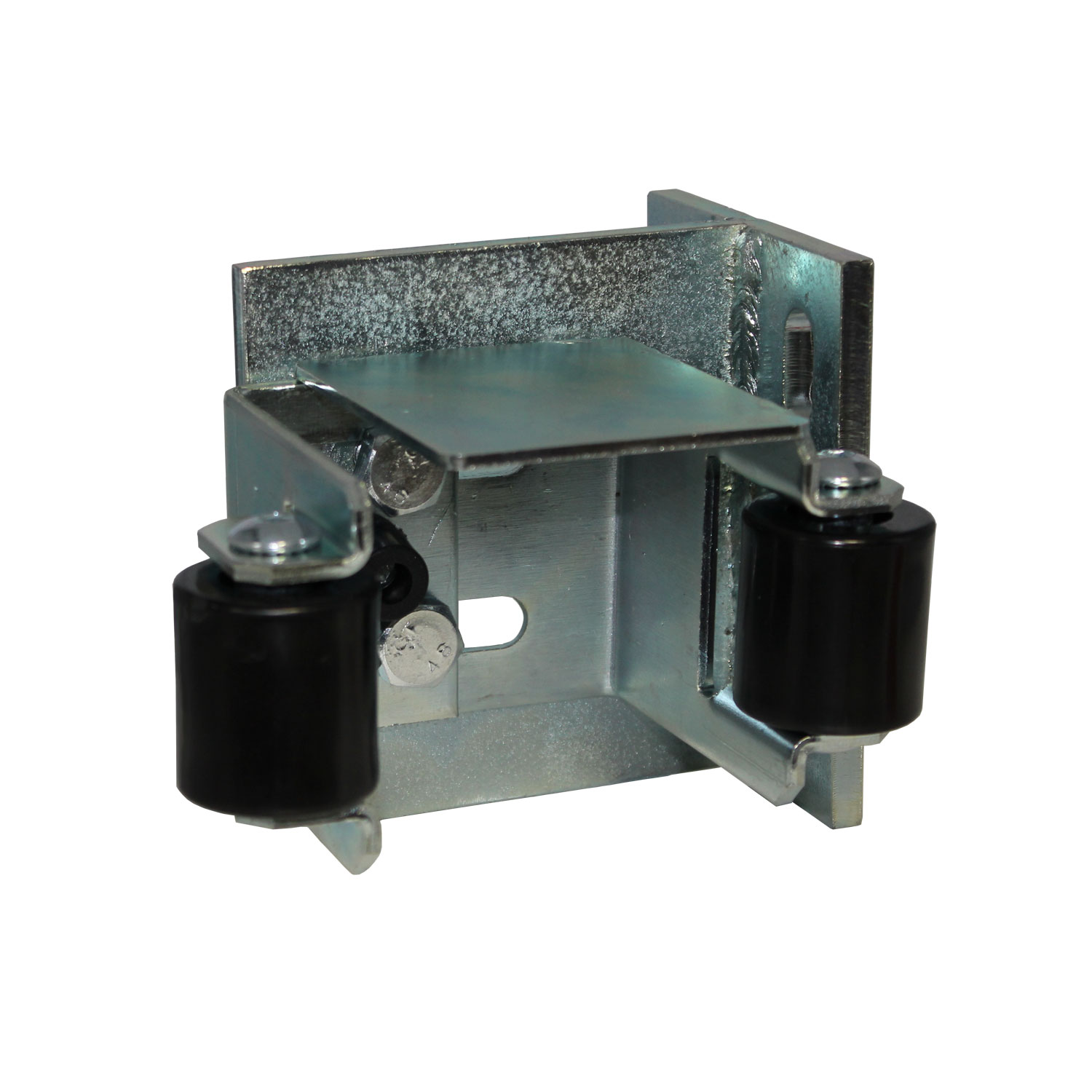

Four Point Roller System B (ZERO-110mm)

Just like System A, System B is also best suited for heavier gates as the for point roller system shares the load across the four rollers (as opposed to two). The difference is the greater adjustment allowing for gate thicknesses from smallest possible all the way up to 110mm, Also as per system A the adjustment occurs within the slotted channel. The secondary plate optionally can be used to additionally support bracket by welding or screwing to a secondary support post creating a tunnel style installation.

C Channel Section with Nylon Block

This system requires a support post behind the gate on the inside, the C channel option chosen ideally should be same material as the post (Both Steel and Aluminum choices are available).

On the back of the gate a welded 40×40 angle (or screw on Z section, available as an optional item) slides through the nylon block.

Best suited for gates on a grade where the guide system must follow UP/DOWN during the gates operation, Suitable for gates where there is overhead protrusions such as spears, suitable for gates with face mounted cladding to the frame.

White and Black nylon block options are available.

Gate Catcher/Receiver Meeting Point

Multiple options available to choose from based on the gates total thickness including and cladding material if applicable. It is recommended to use a gate catcher that is 10mm greater than the gate thickness. All catchers are available with offset brackets allowing for closing behind a post (as opposed to up to a post).

Sliding Gate Wheel Options

80mm DOUBLE WHEEL

The 800mm bearing wheels screw (or weld) directly to the bottom of the gate tubing without any need for cutting, the supported load between the set on each end of the gate is 900KG.

100mm DOUBLE WHEEL

The 100mm bearing wheels screw (or weld) directly to the bottom of the gate tubing without any need for cutting, the supported load between the set on each end of the gate is 1100KG.

Sliding Gate Ground/Floor Track

The sliding gate ground track is formed from galvanized steel to the R10 profile, this profile is proven to be the smoothest operation for the gate wheels without any negative characteristics like the older v groove designs.

The track is secured to the driveway using plugs and screws or knock in’s such as anchor nails, its important to use a fixing that does not protrude greater than 3-4mm to prevent contact with the gate wheels.

✓ Galvanized Steel

✓ Elongated 6mm holes allow for adjustment before final tie down

✓ Suits all R10 gate wheels

Gate Stopper

The gate stopper is a crucial part to any sliding gate installation, the stop is installed at the end of the open position to prevent the gate from being opened past the normal open point which prevents the sliding gate from coming off the track (or out of the top guiding system.

✓ Rubber Bumper

✓ 145mm High

✓ 10mm stem and 6mm base steel thickness